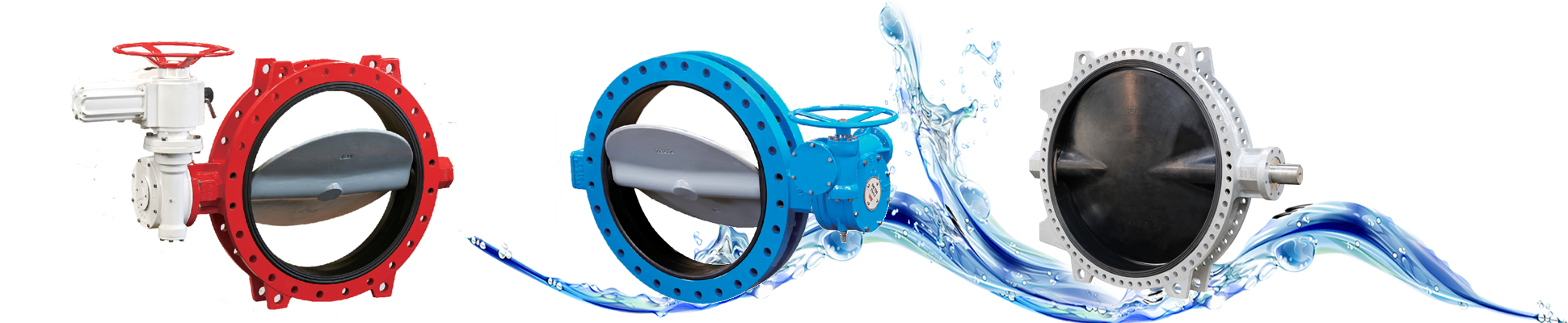

UD Series Butterfly valve chu a thutna nem tak a ni

UD Series soft sleeve seated butterfly valve chu Wafer pattern a ni a, flanges a nei ,a hmai leh hmaiah EN558-1 20 series wafer type angin a awm.

Ziarang:

1.Correcting holes chu flange-ah standard angin siam a ni a, installation laiin siamthat awlsam.

2.Through-out bolt emaw, a sir khata bolt emaw hman tur. Replace leh maintenance awlsam tak a ni.

3.Soft sleeve seat hian taksa chu media atanga a isolate thei.

Product hman dan tur zirtirna

1. Pipe flange standard chu butterfly valve standard nen a inmil tur a ni; welding neck flange, butterfly valve atana specialized flange emaw integral pipe flange emaw hman rawtna; slip-on welding flange hmang suh, supplier chuan user in slip-on welding flange a hman theih hmain a remti hmasa tur a ni.

2. Installation hmaa condition hman dan chu butterfly valve performance inang hman a nih leh nih loh enfiah tur a ni.

3. Installation hmangtuin valve cavity sealing surface a tihfai hmain bawlhhlawh a awm loh nan enfiah hmasa phawt ang che; a rualin pipe chu welding slag leh bawlhhlawh dangte dahna tur a ni.

4.Instal lai hian disc chu pipe flange nen a inhnaih loh nan disc chu khar position-ah a awm tur a ni.

5. Valve seat tawp pahnih hian flange seal angin hna an thawk a, butterfly valve dah hunah extra seal a ngai lo.

6. Butterfly valve hi eng hmunah pawh (vertical, horizontal emaw tilt) dah theih a ni. Butterfly valve lian size operator nei chuan bracket a mamawh mai thei.

7. Butterfly valve phurh emaw dahkhawm emaw a inhnaih chuan butterfly valve chu a sealing theihna a tihtlem phah thei. Butterfly valve disc chu thil khauh takah a tlak loh nan leh he hun chhunga sealing surface a chhiat loh nan 4 ° atanga 5 ° angle position-ah hawn tur a ni.

8. Install hmain flange welding dik leh dik loh enfiah hmasa phawt la, butterfly valve dah hnua welding hian rubber leh preservation coating a tichhia thei.

9. Pneumatic hmanga operated butterfly valve hman hunah chuan air source chu a vawt leh fai reng tur a ni a, chutiang chuan thil dang pneumatic operator-a lut lo tur leh hnathawh dan a nghawng loh nan.

10. Purchasing order-a tarlan special requirement awm lovin butterfly valve hi vertical-a dah theih chauh a ni a, in chhunga hman tur chauh a ni.

11. Case of disorder, a chhan hriatchhuah, harsatna chinfel, butterfly valve chu tharum hmanga hawn emaw khar emaw turin lever operator chu arm of force hmangin knock, hit, prize emaw sei emaw tur a ni lo.

12. A dahna leh hman loh chhung hian butterfly valve te chu a vawt reng tur a ni a, thlamuanna hmunah dah tur a ni a, a chhehvel thil tha lo tak tak, leimin laka awm loh tur a ni.

Dimension hrang hrang: 1.1.

| DN | A | B | H | D0 | C | D | K | d | N-do tih a ni | 4-M a ni | b | D1 | D2 | N-d1 | F | Φ2 a ni | W | J | H1 | H2 | ||||

| 10 | 16 | 10 | 16 | 10 | 16 | 10 | 16 | |||||||||||||||||

| 400 a ni | 400 a ni | 325 a ni | 51 | 390 a ni | 102 a ni | 580 a ni | 515 a ni | 525 a ni | 460 a ni | 12-28 thleng a ni | 12-31-ah a awm | 4-M24 a ni | 4-M27 a ni | 24.5 a ni | 175 a ni | 140 a ni | 4-18 thleng a ni | 22 | 33.15 a ni | 10 | 36.15 a ni | 337 a ni | 600 a ni | |

| 450 a ni | 422 a ni | 345 a ni | 51 | 441 a ni | 114 a ni | 640 a ni | 565 a ni | 585 a ni | 496 a ni | 16-28-ah a awm | 16-31-ah a awm | 4-M24 a ni | 4-M27 a ni | 25.5 a ni | 175 a ni | 140 a ni | 4-18 thleng a ni | 22 | 37.95 a ni | 10 | 40.95 a ni | 370 a ni | 660 a ni | |

| 500 a ni | 480 a ni | 378 a ni | 57 | 492 a ni | 127-ah a awm | 715 a ni | 620 a ni | 650 a ni | 560 a ni | 16-28-ah a awm | 16-34-ah a awm | 4-M24 a ni | 4-M30 a ni | 26.5 a ni | 175 a ni | 140 a ni | 4-18 thleng a ni | 22 | 41.12 a ni | 10 | 44.12 a ni | 412 a ni | 735 a ni | |

| 600 a ni | 562 a ni | 475 a ni | 70 | 593 a ni | 154 a ni | 840 a ni | 725 a ni | 770 a ni | 658 a ni | 16-31-ah a awm | 16-37-ah a awm | 4-M27 a ni | 4-M33 a ni | 30 | 210 a ni | 165 a ni | 4-22 inkar a ni | 22 | 50.63 a ni | 16 | 54.65 a ni | 483 a ni | 860 a ni | |

| 700 a ni | 624 a ni | 543 a ni | 66 | 695 a ni | 165 a ni | 910 a ni | 840 a ni | 840 a ni | 773 a ni | 20-31 ah a awm | 20-37 thleng a ni | 4-M27 a ni | 4-M33 a ni | 32.5 a ni | 300 a ni | 254 a ni | 8-18 thleng a ni | 30 | 63.35 a ni | 18 | 71.4 a ni | 520 a ni | 926 a ni | |

| 800 a ni | 672 a ni | 606 a ni | 66 | 795 a ni | 190 a ni | 1025 a ni | 950 a ni | 950 a ni | 872 a ni | 20-34 inkar a ni | 20-41 ah a awm | 4-M30 a ni | 4-M36 a ni | 35 | 300 a ni | 254 a ni | 8-18 thleng a ni | 30 | 63.35 a ni | 18 | 71.4 a ni | 586 a ni | 1045 a ni | |

| 900 a ni | 720 a ni | 670 a ni | 110 a ni | 865 a ni | 200 a ni | 1125 a ni | 1050 a ni | 1050 a ni | 987 a ni | 24-34-ah a awm | 24-41 ah a awm | 4-M30 a ni | 4-M36 a ni | 37.5 a ni | 300 a ni | 254 a ni | 8-18 thleng a ni | 34 | 75 | 20 | 84 | 648 a ni | 1155 a ni | |

| 1000 a ni | 800 a ni | 735 a ni | 135-ah a awm | 965 a ni | 216 a ni | 1255 a ni | 1160 a ni | 1170 a ni | 1073 a ni | 24-37-ah a awm | 24-44-ah a awm | 4-M33 a ni | 4-M39 a ni | 40 | 300 a ni | 254 a ni | 8-18 thleng a ni | 34 | 85 | 22 | 95 | 717 a ni | 1285 a ni | |

| 1100 a ni | 870 a ni | 806 a ni | 150 a ni | 1065 a ni | 251 a ni | 1355 khan a lo piang a | 1270 a ni | 1270 a ni | 1203 a ni | 28-37 ah a awm | 28-44 ah a awm | 4-M33 a ni | 4-M39 a ni | 42.5 a ni | 350 a ni | 298 a ni | 8-22 inkar a ni | 34 | 95 | ## | 105 a ni | 778 a ni | 1385 khan a lo piang a | |

| 1200 a ni | 940 a ni | 878 a ni | 150 a ni | 1160 a ni | 254 a ni | 1485 khan a lo piang a | 1380 khan a lo piang a | 1390 khan a lo piang a | 1302 a ni | 28-41 ah a awm | 28-50 thleng a ni | 4-M36 a ni | 4-M45 a ni | 45 | 350 a ni | 298 a ni | 8-22 inkar a ni | 34 | 105 a ni | 28 | 117 a ni | 849 a ni | 1515 khan a lo piang a | |

| 1400 a ni | 1017 a ni | 993 a ni | 150 a ni | 1359 khan a lo piang a | 279 a ni | 1685 khan a lo piang a | 1590 khan a lo piang a | 1590 khan a lo piang a | 1495 khan a lo piang a | 28-44 ah a awm | 28-50 thleng a ni | 8-M39 a ni | 8-M45 a ni | 46 | 415 a ni | 356 a ni | 8-33 ah a awm | 40 | 120 a ni | 32 | 134 a ni | 963 a ni | Kum 1715 khan a lo piang a | |

| 1500 a ni | 1080 a ni | 1040 a ni | 180 a ni | 1457 khan a lo piang a | 318 a ni | 1280 a ni | 1700 khan a lo piang a | Kum 1710 khan a lo piang a | 1638 khan a lo piang a | 28-44 ah a awm | 28-57 ah a awm | 8-M39 a ni | 8-M52 a ni | 47.5 a ni | 415 a ni | 356 a ni | 8-33 ah a awm | 40 | 140 a ni | 36 | 156 a ni | 1039 a ni | 1850 khan a lo piang a | |

| 1600 khan a lo piang a | 1150 a ni | 1132 a ni | 180 a ni | 1556 khan a lo piang a | 318 a ni | Kum 1930 khan a lo piang a | 1820 khan a lo piang a | 1820 khan a lo piang a | 1696 khan a lo piang a | 32-50 thleng a ni | 32-57 ah a awm | 8-M45 a ni | 8-M52 a ni | 49 | 415 a ni | 356 a ni | 8-33 ah a awm | 50 | 140 a ni | 36 | 156 a ni | 1101 a ni | 1960 khan a lo piang a | |

| 1800 khan a lo piang a | 1280 a ni | 1270 a ni | 230 a ni | Kum 1775 khan a lo piang a | 356 a ni | 2130 a ni | 2020 a ni ang | 2020 a ni ang | 1893 khan a lo piang a | 36-50 thleng a ni | 36-57-ah a awm | 8-M45 a ni | 8-M52 a ni | 52 | 475 a ni | 406 a ni | 8-40 thleng a ni | 55 | 160 a ni | 40 | 178-ah a awm | 1213 a ni | 2160 a ni | |

| 2000 khan a lo piang a | 1390 khan a lo piang a | 1350 khan a lo piang a | 280 a ni | 1955 khan a lo piang a | 406 a ni | 2345 a ni | 2230 a ni | 2230 a ni | 2105 a ni | 40-50 inkar a ni | 40-62 ah a awm | 8-M45 a ni | 8-M56-ah a awm | 55 | 475 a ni | 406 a ni | 8-40 thleng a ni | 55 | 160 a ni | 40 | 178-ah a awm | 1334 khan a lo piang a | 2375 a ni |