Butterfly valve chi hrang hrang a awm a, classification method pawh a tam hle.

1. Structural form hmanga thliar hran

(1) .concentric butterfly valve chu a awm a; (2) butterfly valve pakhata awm; (3) vawi hnih- .eccentric butterfly valve a ni; (4) butterfly valve pathum awmna

2. Sealing surface material a zirin classification

(1) Butterfly valve nghet tak

(2) Metal chi hrang hrang, hard-sealed butterfly valve. Sealing pair hi metal hard material atanga metal hard material atanga siam a ni.

3. Sealed form hmanga thliar hran

(1) Butterfly valve chu forced sealed a ni.

(2) Pressure sealing butterfly valve chu a chhuak thei lo. Seal pressure hi seat emaw plate emaw a elastic sealing element atanga siam a ni.

(3) Butterfly valve chu automatic-a sealed a ni. Seal specific pressure chu medium pressure hian a siam chhuak nghal vek a ni.

4. Hnathawh pressure a zirin classification

(1) Vacuum butterfly valve chu a awm a. Butterfly valve hmanga hnathawhna pressure standard atmosphere aia hniam zawk.

(2) Pressure hniam tak nei butterfly valve. Butterfly valve a ni a, a nominal pressure chu PN≤1.6MPa a ni.

(3) Pressure hniam tak nei butterfly valve. Nominal pressure PN chu butterfly valve 2.5∽6.4MPa a ni.

(4) Pressure sang tak nei butterfly valve. Nominal pressure PN chu butterfly valve 10.0∽80.OMPa a ni.

(5) Ultra-high pressure hmanga siam butterfly valve a ni. Butterfly valve chu a nominal pressure PN <100MPa a ni.

5. Connection mode hmanga thliar hranna

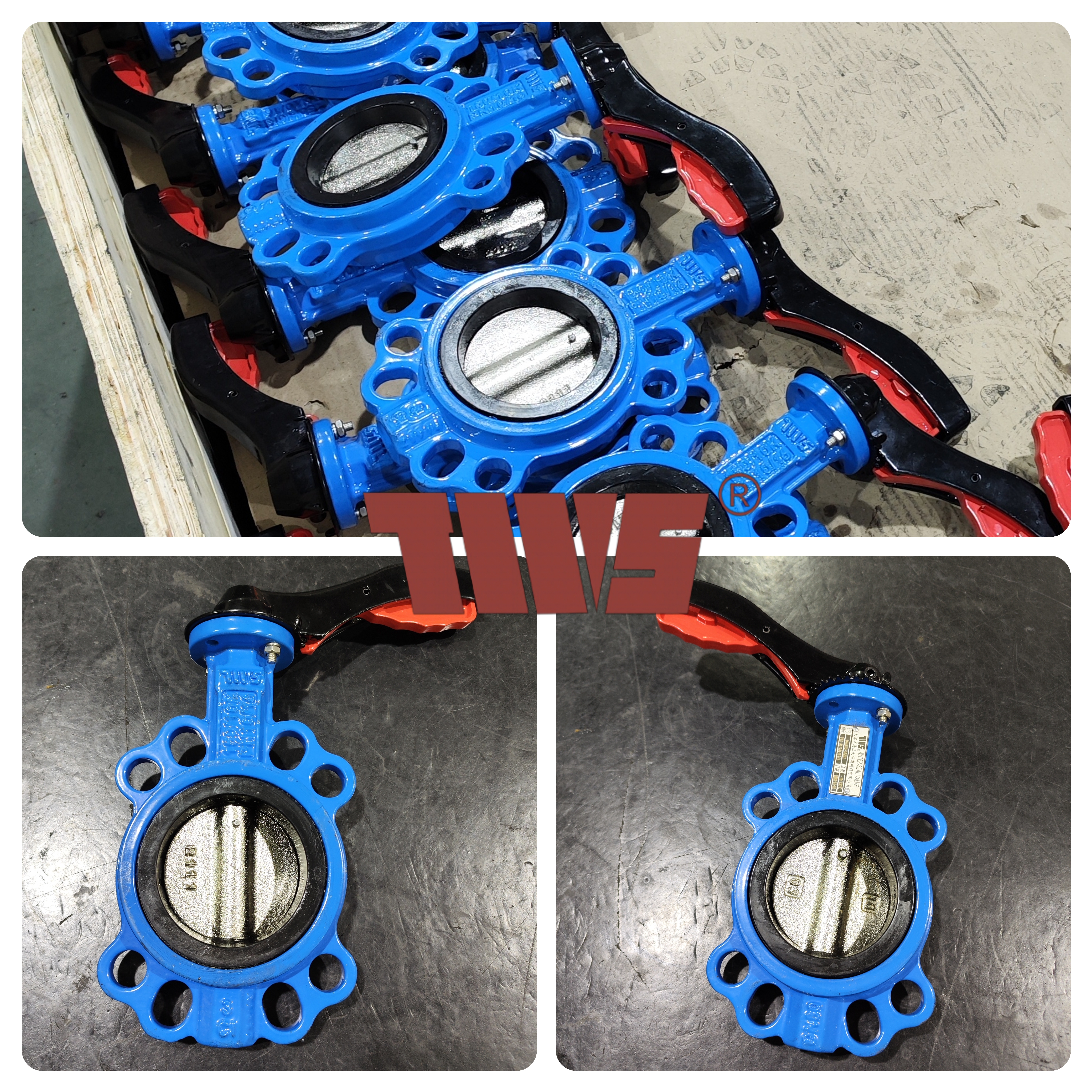

(1) .Wafer butterfly valve hmanga siam a ni

(2) Flange butterfly valve hmanga siam a ni

(3) Lug hnim hring valve

(4) Welded butterfly valve hmanga siam a ni

Concentric Butterfly valve hi valve chi khat a ni a, circular butterfly plate hmanga hawn leh khar a ni a, valve stem inher danah fluid channel chu a hawng a, a khar a, a siamrem bawk. Butterfly valve-a butterfly plate chu pipe diameter lam hawiin dah a ni. Butterfly valve body cylindrical channel ah chuan disc butterfly plate chu axis vel ah a inher a, rotation Angle chu 0 leh 90 inkar a ni a, rotation 90 a thlen chuan valve chu a inhawng kim vek a ni.

In sak leh dahna kawng pawimawh tak tak

1) Installation position, height, import leh export direction te hian design mamawh a tlin tur a ni a, connection pawh a nghet leh tight tur a ni.

2) Thermal insulation pipe-a manual valve chi hrang hrang dahte handle chu hnuai lam hawia dah tur a ni lo.

3) Valve hi dah hmain pawn lam atanga enfiah hmasak tur a ni a, valve hming plate chuan tuna national standard “General Valve Mark” GB 12220-a thupekte a tlin tur a ni a, valve hnathawhna pressure 1.0 MPa aia tam leh main pipe-a cutting off nei tan chuan installation hmain strength leh tight performance test neih tur a ni a, qualified hnuah hman tur a ni. Strength test-ah chuan test pressure hi nominal pressure aiin a let 1.5 a ni a, a hun chhung hi 5min aia tlem lo a ni. Valve shell leh packing chu leakage awm lovin qualified tur a ni. Tightness test atan chuan test pressure chu nominal pressure aiin a let 1.1 a ni a; test pressure chu test hun chhung atan GB 50243 standard a tlin tur a ni a, valve seal surface pawh a qualified tur a ni.

Point pawimawh tak takte product thlan dan

1. Butterfly valve control parameter ber chu a specification leh dimension te hi a ni.

2. Butterfly valve hi single plate wind valve a ni a, a structure awlsam, processing awlsam, man tlawm, hnathawh awlsam, mahse adjustment accuracy a tha lo a, ventilation leh air conditioning system atan chauh a tha a, switch emaw coarse adjustment of the occasion atan chauh a tha.

3. Manual, electric emaw zipper type hmanga hnathawh theih a ni a, Angle of 90 range eng pawhah fix theih a ni.

4. Single axial single valve plate avang hian bearing force a tlem a, pressure danglamna lian tak dinhmunah chuan valve service life a tawi laiin flow rate lian tak a ni. Valve hian closed type leh ordinary type, insulation leh non-insulation a nei a.

5. Electric butterfly valve hian dual type control chauh a nei a, electric actuator hi multi-leaf valve nen a inang.

Post hun chhung: Oct-26-2023