Valve connection surface structure hian valve sealing performance, installation method leh pipeline system-a rintlakna a nghawng nghal vek a ni.TWSmainstream connection form leh an mizia te chu he thuziak ah hian tawi te tein a rawn tarlang ang.

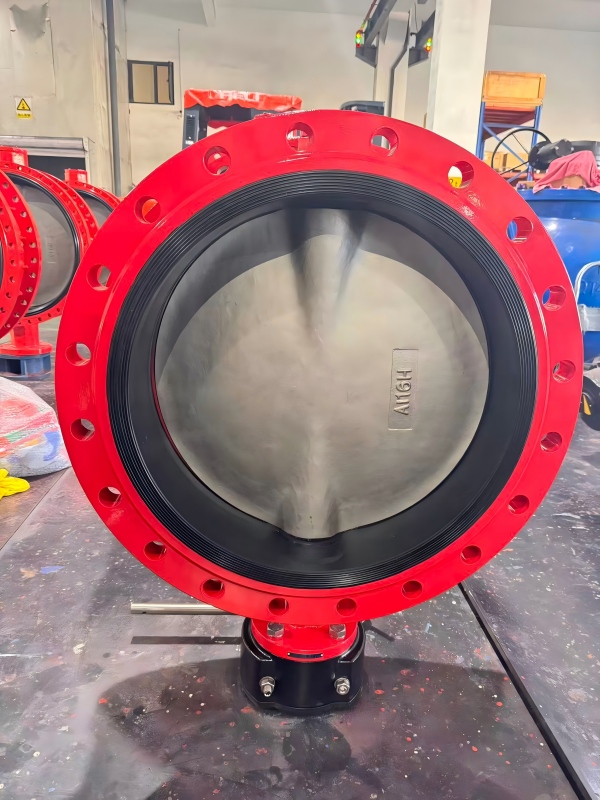

I. Flanged hmanga inzawmna a awm

Universal connection method hian paired flanges bolted fastening hmangin sealing a ti thei a ni.

Sealing surface chi hrang hrang hman tlanglawn:

-Protruding surface: Design hman tlanglawn ber, sealing surface protruding 2-3mm nei, pressure range zau tak (PN10-PN25) atana tha.

-Concave-convex surface: sealing performance tha zawk, kang thei leh toxic media atan a tha.

-Groove surface: sealing tha ber, media hlauhawm tak tak leh high pressure condition atan hman thin.

-Ring connection surface: Metal ring gasket, pressure sang leh temperature sang taka hman tur atana siam a ni. A thatna: Sealing rintlak leh disassembly awlsam tak a ni.

A that lohna: volume leh weight lian tak, man to tak.

II.Wafer Connection a awm bawk

Valve hian non-flanged design a nei a, pipe flanges inkarah bolt sei tak tak hmangin a nghet a ni. Thil pawimawh tak takte chu a structure compact, a sak rit lo, leh a man tlawm zawk te a ni. Mahse, installation standard sang tak a mamawh a, enkawl a harsa hle. He design hi hman lar tak a nibutterfly valve te pawh a awmlehcheck valve te a awm bawk.

III.Thread hmanga inzawmna siam

Threaded connection hi mechanical connection method a ni a, threaded fastener hmangin part hrang hrang inzawmkhawm a ni a, engtik lai pawhin a disassemble theih a ni.

Sealing thatna: A siam chhuah tamna hian siamna senso a ti tlem hle a, hei hi connection hmanraw man tlawm ber pawl a ni.

A that lohna: Vibration leh impact load hnuaiah a loosen awlsam a, thread bul hnaia stress concentration hian a fatigue strength a ti hniam bawk.

IV. Welding hmanga inzawmna siam

Permanent connection rintlak ber.

-Type: Butt welding: A chakna sang tak, fluid resistance hniam, hnathawhna hmun harsa tak takah pawh a tha.

-Plug-in welding connection: Install a awlsam a, pipe te tak te tan pawh a tha. A thatna: Zero leakage, vibration-resistant a ni.

A chhiatna: 5. Disassembly harsat. Connection chi dang: Clamping connection: Sanitary industry-a tihfai awlsamna atana hman thin. Sleeve connection: Instrumentation leh hydraulic system-ah te hman a ni.

Thil thlan tur: 1.1.

1. Pressure leh temperature a zirin a hman dan tur thlang rawh: pressure sang leh temperature sang chu welded emaw ring connection emaw a ni tur a ni.

2. Medium characteristics atanga thlirin: Media hlauhawm tan chuan welding emaw tenon-joint surface emaw siam a tha.

3. Installation leh maintenance ngaihtuah: Flange connection tihchhiat fo thin.

4. Cost leh Space: Wafer hi a economical a, a compact bawk.

V. Tawpna :

Connection dik tak hi pipeline himna leh performance atana pawimawh tak a ni. Expert kaihhruaina leh competitive quotes te chu kan...butterfly valve a ni, gate valve a ni, lehcheck valve te a awm bawk. InbepawpTWSi mamawh tur solution tha ber zawng turin.

Post hun chhung: Nov-25-2025