Butterfly valve te pawh a awmliquid leh gas hrang hrangte luang chhuak control-na kawngah hmun pawimawh tak an chang a ni. Butterfly valve chi hrang hrang zingah lug butterfly valve leh wafer te pawh a awmbutterfly valve te pawh a awmtih hi duhthlanna hman lar tak pahnih a ni. Valve chi hnih hian hnathawh danglam bik an nei a, hmanna bik atan pawh a tha hle.TWShe thuziak-ah hian an inmilna leh an danglamnate chu a chhui ang a, valve dik tak i thlan hunah thutlukna dik siam tûra ṭanpui che a beisei a ni.

I. An inanna te.

1. HnathawhPrinciple tih a ni.

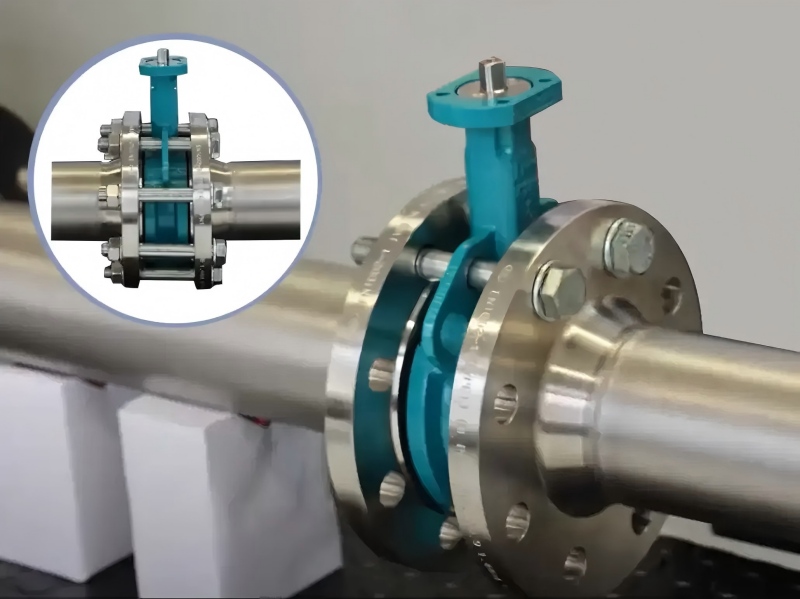

Wafer type butterfly valve leh lug type butterfly valve pahnih hian valve disc chu rotate-in medium flow rate an control vek a ni. Valve disc rotation angle hi 0 atanga 90 degree inkar chauh a ni thei a, chu chu, valve chu 90 degree-ah a inhawng kim a, 0 degree-ah a khar kim vek tihna a ni. Hei hi butterfly valve hnathawh dan a ni.

2. Chutiang bawkHmai leh Hmai

Wafer butterfly valve leh lug butterfly valve te hi thin type anga siam a ni a, hmun tlem zawk luahtu a ni a, pipeline system-a hmun tlemte awmnaah dahna atan a tha hle.

3. Standardized design hmanga siam: 1.1.

An pahnih hian international industrial standard an zawm a, standard flange nena inzawm awlsam an ni a, system awm tawhah pawh awlsam taka thlak theih an ni.

| Ruahmanna | Nihphung pangngai |

| Process Design (Process Design) a ni | EN593 | API609 a ni |

| Hmai leh Hmai | EN558 a ni a | ISO5752 a ni a | API608 a ni | BS5155-4 ah a awm |

| Top Flange a ni | ISO5211 a ni |

| Flange Drilling hmanga siam a ni | PN6 | PN10 ah hian | PN16 ah hian | ASME B16.5 CL150 |.. A rilru a hah lutuk chuan a rilru a buai em em a JIS 10K a ni |

| Pressure Rating a ni | PN6 | PN10 ah hian | PN16 ah hian | PN25 ah hian | CL150 a ni | JIS 10K a ni |

| Sealing Test a ni | ISO5208 a ni a | API598 a ni | EN12266-1 a ni |

II.Engnge's a danglamna chu?

Wafer type butterfly valve leh lug type butterfly valve pahnih hian butterfly valve connection form a kawk a, structural length inang leh thil tum inang a nei a, mahse design, installation, application, cost leh thil dang dangah erawh danglamna lian tak a awm thung.

1. 1. A rilru a hah lutuk chuan a rilru a buai em em a.Ruangam siamDifferences te pawh a awm

Lug butterfly valve: Valve body tawp pahnih hi threaded lugs hmanga siam a ni a, chu chu valve fixing atan a tha zawk.

Wafer butterfly valve: Chu ai chuan threaded inserts a nei lo va, flange pahnih inkarah clamp a ni a, pipeline flange leh valve body kaltlangin bolt kal tlangin a siam that a ni. Chu chu, pipeline flange-a bolt-te pressure hmanga design a ni tihna a ni.

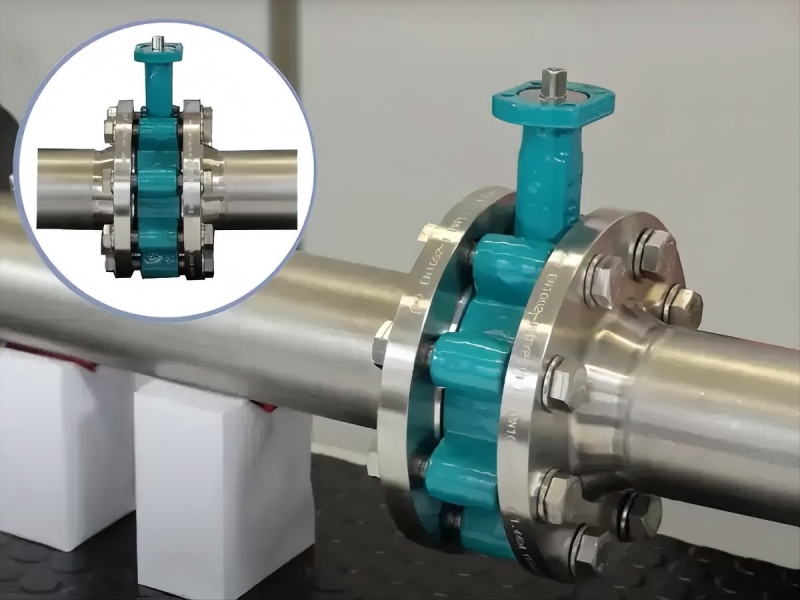

2. 2. A rilru a hah lutuk chuan a rilru a buai em em a.Installation a niProcess tih hi a ni.

Lug butterfly valve hi pipeline enkawl ngai emaw, tihchhiat fo ngai emaw tan a tha hle. Threaded insert hi pipeline system pumpui tichhe lovin install leh disassemble awlsam tak a ni. Butterfly valve chhuak chu pipeline tawp lamah dahin terminal valve atan hman theih a ni.

- Valve body-a pressure awm loh nan lugs te chu flange bolt te nen a inmil em tih enfiah tur.

- Leakage awm loh nan a tul hunah gasket material dik tak hmang la, a bik takin medium pressure system-ah chuan.

- Valve chhunga pressure inang tlang taka awm theih nan bolt te chu a rualin khauh takin khih rawh.

Wafer butterfly valve hi pipeline tawp pahnih inzawmkhawmna atan hmun a tlem zawkna hmunah a tha zawk a, mahse a inthen theih avangin terminal valve atan hman theih a ni lo.

- Flange compatibility (eg ANSI, DIN) enfiah la, sealing a awm theih nan.

- Machine body a deformation loh nan flange bolt te khauh lutuk loh tur.

- System-ah pipeline vibration tlem ber hmanga dah a ni a, a loose loh nan.

3. Sealing Mechanism hman dan tur.

Lug butterfly valve hian threaded connection leh safety bolt avang hian seal khauh zawk a pe a, leak free operation a tichiang a, fluid backflow a veng bawk.

Chutih rualin, wafer type butterfly valve hian sealing rintlak tak a neih theih nan flange pahnih inkara compression a rinchhan a, chuvangin misalignment leh leakage awm loh nan pipeline nena inmil vek tura dah a ngai a ni.

4. DN&PN

- Butterfly valve-a wafer hi DN600 aiin a te zawk tlangpui a, single flange butterfly valve hi diameter lian zawk atan hman theih a ni. A tlangpuiin pressure ≤ PN16 a nih chuan an tha hle.

-Lug butterfly valve hian diameter lian zawk a nei a, pressure level sang zawk, PN25 thleng a tuar thei a, a chhan chu lug butterfly valve dahna hi a him zawk a ni.

5. C. A rilru a hah lutuk chuan a rilru a buai em em aost

Lug butterfly valve leh wafer butterfly valve te hi a man tlawm dan a inang lo hle.

Wafer butterfly valve hi a man tlawm zawk tlangpui a, a chhan chu design awlsam zawk, processing awlsam zawk leh material mamawh tlem zawk a nih vang a ni.

Lug butterfly valve hian threading a mamawh avangin machining process hi a buaithlak hle.

III. C. A rilru a buai em em aonclusion tih a ni

Lug butterfly valve leh wafer butterfly valve pahnih hi fluid flow control nan hman a ni a, mahse heng pahnih inkarah hian design, installation, sealing, diameter, pressure rating leh cost-ah danglamna lian tak a awm a ni. Duhthlan hunah chuan mamawh bik a zirin a hriat theih a ni: tihchhiat leh enkawl fo a ngai a nih chuan beng chhuak chi thlan a tha a Space a tight a, cost a ngaihtuah chuan wafer on design hi a tha zawk. Heng danglamna te hi hriatthiamna hian valve inmil zawk thlan nan leh flow control tha leh rintlak tak i neih theih nan a pui thei che a ni.TWSquality sang tak neihna atana thawhpui rintlak mai a ni lobutterfly valve te pawh a awm, mahse technical accumulation thuk tak leh solution puitling tak tak a nei bawkgate valve te a awm bawk, check valve te a awm bawk, boruak chhuahna valve, etc. Fluid control hian eng ang pawhin mamawh mahse, professional leh complete one-stop valve support kan pe thei che a ni. Thawhhona emaw technical consultation emaw neih tumna i neih chuan engtik lai pawhin min rawn biak theih reng e.

Post hun chhung: Dec-11-2025