Application pakhat atana seal material dik thlan huna ngaihtuah tur pawimawh thenkhat chu engte nge ni?

A man to tak leh qualified colors te pawh a awm

Seal awm theihna tur

Sealing system-a nghawng nei zawng zawng: eg temperature range, fluid leh pressure

Heng zawng zawng hi i sealing system-a ngaihtuah tur pawimawh tak tak a ni. Factor zawng zawng hriat vek a nih chuan material dik thlan a awlsam ang.

Mahse a mamawh hmasa ber chu a thil siam chu a chhe thei lo tur a ni. Chuvangin ngaihtuah hmasak tur chu technical performance a ni. Performance factor atang hian tan ila ang u.

System dam chhung leh senso hi thil pawimawh tak a ni (TIanjin Tanggu Tui-Seal Valve Co.,ltd) ngaihtuah tur a ni. Thil zawng zawng hian i application performance a nghawng vek ang. A hman dan azirin design factors ngaihtuah a pawimawh hle. Hei hian material hman, hardware shape leh production process te a huam a ni. Environment factor ngaihtuah tur a awm bawk a, chungte chu: pressure, temperature, time, assembly leh media te hi a ni.

elastomer a ni

Elastomer hi an elasticity tha em avangin an lar hle. Material dang reng reng hian elasticity level inang an nei lo.

Thil dang polyurethanes leh thermoplastics te hi elastomer aiin pressure an tuar thei zawk hle.

Rubber material hi hmanraw hrang hrangah hman theih a ni.

Mechanical property pawimawh tak takte chu

elasticity a ni

a khauhna (hardness) a ni

tensile chakna a ni

Thil pawimawh dangte chu

• .Compression set a ni

• .lumna do theihna

• .temperature hniam tak a awm thei

• .chemical nena inmil theihna

• .Kum upa lam dona

• .abrasion laka inven theihna

A pawimawh ber chu rubber material elasticity a ni. Hemi chungchang hi i zir belh zel ang u.

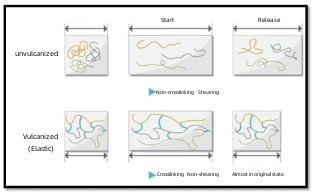

Elasticity hi vulcanization atanga lo chhuak a ni. Elastomeric materials, vulcanized rubber ang chi te chu a inthlak danglam chuan a pianphung hmasaah a kir leh ang.

Inelastic materials, unvulcanized rubber ang chi te chu a deform a nih chuan a dinhmun hmasaah a kir leh tawh lovang. Vulcanization (chutiang ang chidouble flange hmanga siam a ni) chu rubber chu elastomeric material-a chantirna a ni.

Elastomer thlan dan hi a bik takin:

• .hnathawhna hmun lum leh vawt range

• .Liquid leh gas laka invenna

• .Weathering, ozone leh UV rays laka inven theihna

Elastomer thlan dan hi a bik takin:

• .hnathawhna hmun lum leh vawt range

• .Liquid leh gas laka invenna

• .Weathering, ozone leh UV rays laka inven theihna

Valve sealing surface material thlan huna ngaihtuah tur thil paruk

Sealing surface hi a hnathawhna hmun pawimawh ber a nivalve a ni, sealing surface quality hian direct-in service life a nghawng a nivalve a ni, leh sealing surface-a thil awmte hi sealing surface quality enfiahna atana thil pawimawh tak a ni. Chuvangin, valve sealing surface material thlan hunah a hnuaia thilte hi ngaihtuah tur a ni:

1. A niCorrosion laka inven theihna. “Corrosion” chu medium hnathawh avanga sealing surface chunglam a chhiat dan a ni. Sealing surface chunglam a chhe a nih chuan sealing performance chu a chiang thei lo va, chuvangin sealing surface-a material chu corrosion-resistant a ni tur a ni. Material pakhat corrosion resistance hi a material composition leh a chemical stability ah a innghat ber a ni.

2. A niAnti-abrasion a ni. “Scratch” tih hian sealing surface relative movement-a material friction avanga chhiatna thleng tihna a ni. Hetiang chhiatna hian sealing surface a tichhia ngei ang. Chuvangin, sealing surface material hian anti-scratch property tha tak a nei tur a ni a, a bik takin gate valve tan chuan. Material pakhat scratch resistance hi a chhunga thil awm dan atanga teh a ni fo thin.

3. A niErosion laka inven theihna. “Erosion” chu medium chu sealing surface atanga chak taka a luang chhuah chuan sealing surface tihchhiatna a ni. Hetiang chhiatna hi temperature sang leh pressure sang tak steam media-a hman thin throttle valve leh safety valve-ah a langsar zawk a, sealing performance chhiatnaah pawh nghawng lian tak a nei bawk. Chuvangin, erosion resistance pawh hi sealing surface materials atana thil pawimawh tak pakhat a ni.

4. A niHardness engemaw zat a nei tur a ni a, a hardness chu working temperature tarlan hnuaiah nasa takin a tlahniam ang.

5Sealing surface leh body material linear expansion coefficient chu a inang tur a ni a, hei hi sealing ring structure atan a pawimawh zawk a, chutiang chuan extra stress leh temperature sang takah loosening a awm loh nan.

6 a niTemperature sang tak hnuaia hman a nih chuan anti-oxidation, thermal fatigue resistance leh thermal cycle issues a awm tawk tur a ni.

Tuna kan dinhmun hnuaiah hian a chunga kan sawi tawh ang hian sealing surface material hmuh a harsa hle. Valve chi hrang hrang leh hman dan hrang hrang a zirin aspect thenkhat mamawh phuhruknaah chauh kan rilru kan pe thei a ni. Entirnan, high-speed media-a hman valve-te chuan sealing surface-a erosion resistance mamawh chu a bik takin an ngaihven tur a ni a; tin, medium-ah hian solid impurities a awm chuan sealing surface material hardness sang zawk thlan tur a ni.

Post hun chhung: Mar-08-2023