- Material thlan dan tur

Valve hniam tak tak te

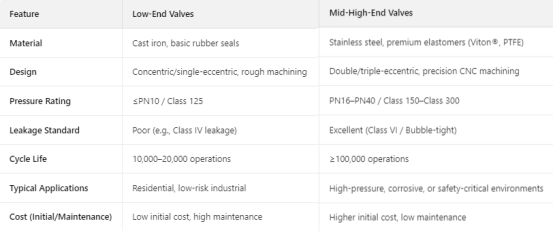

- Taksa/Disc hmanrua te: A tlangpuiin metal man tlawm tak tak hman thin ang chithir hnawih (cast iron) a niemaw, unalloyed carbon steel emaw, boruak khirh takah chuan corrosion resistance nei lo thei a ni.

- Sealing Rings te pawh a awm: Basic elastomers hmanga siam a ni a, chu chuNR (natural rubber) hmanga siam a ni.emaw, low-grade EPDM, chemical laka invenna leh temperature tolerance tlem (eg, ≤80°C / 176°F) emaw a ni thei bawk.

- Shaft a ni: Carbon steel pangngai atanga siam a ni fo thin a, a chunglam tihfai loh a ni a, hnim emaw acidic emaw a nih chuan rust a awm awlsam hle.

Mid-High-End Valve te pawh a awm bawk

- Taksa/Disc hmanrua te: Corrosion resistance leh mechanical strength tha zawk neih nan stainless steel (SS304/316), ductile iron, emaw aluminum bronze ang chi thil tha tak tak hmang rawh.

- Sealing Rings te pawh a awm: FDA-compliant EPDM, NBR, PTFE, emaw Viton® ang chi elastomer tha tak tak hmang rawh, 1999 a ni.thilhlan broader chemical compatibility (eg, oil, acid, emaw solvent laka invenna) leh temperature sang zawk (-20°C atanga 150°C / -4°F atanga 302°F) a ni.

- Shaft a ni: Stainless steel (SS410/316) a siam niin, a chunglam chu polished emaw coated emaw (eg, nickel plating) hmanga siam niin, a chhe lo leh a leak loh nan.

- Structural Design & Thil siam chhuah dan tur

Valve hniam tak tak te

- Design awlsam zawk: Basic concentric emaw single-eccentric emaw structure sealing precision tlemte nei. Disc leh seat hian rough machining a nei thei a, chu chuan friction leh torque a ti sang zawk thei.

- Pungkhawm: A tam zawkah chuan quality control tlemte nen mass-produced a ni a, chu chuan tolerances inmil lo tak a siam thin. Leakage rates hian standard khauh tak a zawm lo thei (eg, ANSI B16.104 Class VI requirements aia tam).

- Actuation tih dan: 1.1.A tlangpuiin manual handle man tlawm tak emaw, basic electric actuator emaw nena paired a ni a, hman fo tur atan a chhe thei lo.

Mid-High-End Valve te pawh a awm bawk

- Design hmasawn tak a ni: Nihphungdouble-eccentric emaw triple-eccentric emaw hmanga siam a nifriction tihtlem nan te, sealing efficiency tihsan nan te, leh wear tih tlem nan te. Entirnan, double-eccentric design hian "wedging effect" a siam a, chu chuan shut-off khauh zawk a siam a ni.

- Thil siam chhuah dik tak: CNC hmanrua precision sang tak hmanga machine hmanga siam a ni a, disc kal dan mumal tak leh seal contact tha ber tur a ni. Leakage rates hian ISO 15848-1 (eg, Bubble-tight Class A) a tlin emaw, a pel emaw fo thin.

- Actuation tih a ni: High-speed, high-cycle application atan premium actuators (pneumatic, hydraulic, emaw intelligent electric actuators) nen a inmil. Model thenkhatah chuan automation atan positioner emaw feedback sensor emaw an dah tel bawk.

3. Hnathawh dan & Rintlakna

Valve hniam tak tak te

- Pressure/Temperature tihkhawtlai a ni: Pressure hniam system (eg, ≤PN10 / Class 125) leh temperature range tawi tak tan a tha. Pressure sang (eg, >PN16) emaw, boruak lum lutuk (-10°C atanga 90°C) emaw-ah a hlawhchham thei.

- Rawngbawlna Nun: Material durability tha lo leh design flaws vangin a tawi a, enkawl emaw thlak emaw fo a ngai (eg, 10,000–20,000 cycles).

- Leakage Risk a awm thei: Seal deformation emaw shaft corrosion emaw chance sang zawk, environment leak emaw system failure emaw a thlen thei.

Mid-High-End Valve te pawh a awm bawk

- Pressure/Temperature tihkhawtlai a ni: Medium-to-high pressure system (eg, PN16–PN40 / Class 150–Class 300) leh temperature range zau zawk (-30°C atanga 200°C / -22°F atanga 392°F) atana siam a ni.

- Rawngbawlna Nun: Hun rei tak chhunga rintlak tura engineer a ni a, cycle life chu operation 100,000 chuang a ni. Premium model thenkhatah chuan lifetime warranty an pe bawk.

- Leakage Control a ni: Advanced seal leh anti-blowout shaft te hian leakage risk a ti tlem a, gas system emaw hazardous fluid handling ang chi hmanraw pawimawh tak tak atan a tha hle.

4. Dilna hrang hrang

Valve hniam tak tak te

- Suitable For: Non-critical, low-risk application, flow control mamawh bulpui nei, chu chu:

- In luah tur tui pekna tur system

- HVAC ductwork awlsam tak a ni

- Pressure hniam taka tui pek emaw, tui chhuahna emaw

- Use In tih loh tur: High-pressure industrial pipeline, corrosive media, emaw himna atana pawimawh hmun (eg, oil & gas, damdawi siamna hmun) te.

Mid-High-End Valve te pawh a awm bawk

- Ideal For: Industrial leh sumdawnna atana hmanraw mamawh tak tak, heng zingah hian:

- Chemical siamna hmun (corrosive fluids) te chu .

- Ei leh in siam chhuah (sanitary standards) 1.1.

- Power siam chhuah (high-temperature steam) 1.1.

- Oil & gas (puak thei lo tur mamawh) .

- Key Standards: International safety leh quality regulation zawm a nih avangin ISO, API, ASME, emaw ATEX-ah certified a ni fo.

5. Cost & Enkawlna tur

Valve hniam tak tak te

- A tir lama Cost: A man tlawm zawk (mid-high-end model aiin 20–50% in a tlem zawk), hei vang hian budget-sensitive project atan pawh a hip hle.

- Enkawlna: Seal thlak fo, shaft lubrication, emaw corrosion siamthat fo avanga hun rei tak chhunga senso sang zawk.

- Downtime Risk a awm thei: Beisei loh taka hlawhchhamna a thlen tam zawk a, industrial setting-a production hlohna a thlen thin.

Valve dik tak thlan dan (eg.TWS Valve a ni)

- Low-End a ni: Hun rei lote chhunga hman tur, thil pawimawh lo tak tak atan a tha a, chutah chuan cost chu ngaih pawimawh ber a ni.

- Mid-High-End-ah a awm a: Hengte hi rintlakna, himna leh hun rei tak chhunga hnathawhna atana hmanraw harsa tak takah invest rawh. Valve thlan hunah media type, operating conditions, leh compliance requirements te ngaihtuah fo ang che.

He inthliarna hian engvangin nge mid-high-end valveD371X-16Q a nihimna leh efficiency ngaih pawimawh hmasa ber industry-ah duh zawk an ni a, low-end option-te erawh chuan basic, cost-driven needs a phuhruk thung.

Soft Seal, Hard Performance a ni theiwafer hnim hring valve a ni, Double flange hmanga siam a ni D34B1X-10Q a ni, Kawngkhar valve, Y-strainer, .Wafer dual plate check valve a awm bawk,-Leak Fredd solutions atana engineer a ni. Tight Seal, Rin tlak loh, I flow Control Expert.

Post hun chhung: Jun-07-2025