1. Structural thlirletna (structure) thlirletna

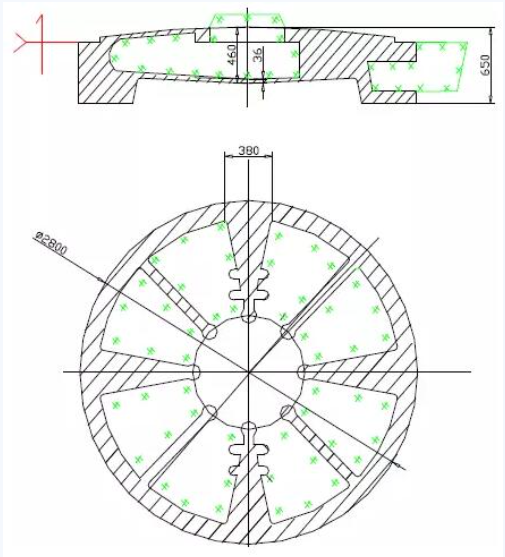

(1) Hei hibutterfly valve a nicake ang maia circular structure a nei a, a chhung lam chu reinforcing rib 8 hmanga inzawm leh thlawp a ni a, a chung lam Φ620 hole chu chhung lam cavity nen a inbiak a, a bak zawng chuvalve a nia khar a, sand core chu siamthat a harsa a, a deform a awlsam bawk. Exhaust leh inner cavity tihfai hian harsatna nasa tak a thlen vek a, Figure 1-ah hian kan hmu a ni.

Castings te wall thickness hi a inang lo hle a, wall thickness sang ber chu 380mm a tling a, wall thickness tlem ber chu 36mm chauh a ni. Casting chu solidified a nih chuan temperature danglamna a lian a, a shrinkage inang lo chuan awlsam takin shrinkage cavities leh shrinkage porosity defects a siam thei a, chu chuan hydraulic test-ah tui a seepage thei ang.

2. Process design: 1.1.

(1) Parting surface chu Figure 1-ah hian kan hmu a, a tawp chu box chunglam chungah khur neiin dah la, a laiah chuan sand core pum pui siam la, core head chu a remchan dan angin sei la, chu chuan sand core chu a nghet thei ang a, box chu a inher chhuah hunah sand core chu a kal thei ang. Stable, a sir lama blind hole pahnih cantilever core head sei zawng chu hole sei zawng aiin a sei zawk a, chuvangin sand core pumpui center of gravity chu core head sir lamah biased a ni a, chu chuan sand core chu fixed leh stable a nih theih nan a pui a ni.

Semi-closed pouring system hman a ni a, a chhungah ∑F: ∑F horizontal: ∑F straight=1:1.5:1.3, sprue hian ceramic tube a hmang a, a chhung lam diameter chu Φ120 a ni a, a hnuai lamah 200×100×40mm refractory brick pahnih dah a ni a, chu chu molten iron chu direct-a a awm loh nan a ni Impact sand mold atan chuan runner hnuai lamah 150×150×40 foam ceramic filter dah a ni a, inner runner chu filter hnuai lama tui khawlkhawmna tank kaltlangin casting hnuai lam nena inmil taka inzawm theih nan 150×150×40 foam ceramic filter dah a ni a, hei hi Figure 2 Essence-a kan hmuh ang hian a ni

(3) Upper mold-ah cavity air hole 14 ∮20 dah la, core head lai takah Φ200 sand core vent hole dah la, a thuk leh lianah cold iron dah la, casting chu balanced solidification a awm theih nan, graphitization expansion principle hmangin cancel rawh Feeding riser hi process yield tihsan nan hman a ni. Sand box lian leh te hi 3600×3600×1000/600mm a ni a, a chakna leh a nghet tawk theih nan 25mm thick steel plate hmanga weld a ni a, Figure 3-a kan hmuh ang hian.

3. Process control dan tur

(1) Modeling: Modeling i tih hmain Φ50×50mm standard sample hmangin resin sand-a compressive strength ≥ 3.5MPa test la, cold iron leh runner chu tighten la, chu chu sand mold-in molten iron-in Chemical expansion a solidified huna graphite a siam chhuah offset theihna tur chakna a nei tling em tih enfiah la, molten iron-in runner part-a hun rei tak a nghawng loh nan sand washing thlen tir turin.

Core siam: Sand core hi reinforcing rib 8 hmangin hmun inang 8-ah then a ni a, chungte chu middle cavity hmangin an inzawm khawm a ni. Middle core head tih loh chu support leh exhaust part dang a awm lo. Sand core fix theih loh leh Exhaust, pouring hnuah sand core displacement leh air holes a lo lang ang. Sand core zau zawng hi a lian avangin hmun riatah a inthen a ni. Mold chhuah hnuah sand core a chhiat loh nan, a leih hnuah pawh a chhe lo ang tih theih nan chakna leh rigidity tling a nei tur a ni. Deformation a awm a, chutiang chuan casting wall thickness inang tlang a awm theih nan. Hemi avang hian a bik takin core bone bik kan siam a, chu chu core bone-ah ventilation rope hmangin kan khih a, chu chu core head atanga exhaust gas lakchhuah nan core siam laiin sand mold chu a compact theih nan kan ti a ni. Figure 4-a kan hmuh ang hian.

(4) Closing box: Butterfly valve chhungril chhunga sand tihfai a harsatzia ngaihtuah chuan sand core pumpui chu paint layer hnih hmanga chei a ni a, a hmasa ber chu alcohol-based zirconium paint (Baume degree 45-55) hmanga brush a ni a, a hmasa ber chu paint leh hal a ni. A vawt hnuah layer pahnihna chu alcohol-based magnesium paint (Baume degree 35-45) hmangin paint la, chutiang chuan casting chu sand-ah a innghat lo va, sintering a awm loh nan, chu chu tihfai theih a ni lo. Core head part chu core bone main structure-a Φ200 steel pipe-ah M25 screw pathum hmangin an khai a, screw cap nei upper mold sand box hmangin fix leh lock a ni a, part tin wall thickness chu a inang tlang em tih enfiah a ni.

4. Melting leh pouring kalphung

(1) Benxi low-P, S, Ti quality sang Q14/16# pig iron hmang la, 40%~60% ratio-in dah la; trace elements P, S, Ti, Cr, Pb, etc. te chu scrap steel-ah khauh takin control a ni a, rust leh oil pawh phal a ni lo , addition ratio chu 25%~40% a ni charge rawn kir leh chu hman hmain shot blasting hmanga tihfai a ngai a, chu chuan charge thianghlim a nih theih nan.

(2) Furnace hnua main component control: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (residual): 0.035% ~0.05%, Mg hnuai lam limit spheroidization enfiahna hnuaiah (residual) a tam thei ang ber ei tur a ni.

(3) Spheroidization inoculation enkawlna: magnesium tlem leh lei tlem lo spheroidizers hman a ni a, addition ratio chu 1.0%~1.2% a ni. Conventional flushing method spheroidization treatment, vawi khat inoculation 0.15% chu package hnuai lama nodulizer-ah khuh a ni a, spheroidization chu tihfel a ni. Chumi hnuah slag chu secondary inoculation 0.35% atan subcontract a ni a, pouring laiin flow inoculation 0.15% tih a ni.

(5) Low temperature fast pouring process hman a ni a, pouring temperature chu 1320°C~1340°C a ni a, pouring hun chhung chu 70~80s a ni. The molten iron chu pouring laiin tihtawp theih a ni lo va, sprue cup chu a khat reng a, chu chu runner kaltlangin mold-ah gas leh inclusions a inrawlh loh nan a ni. cavity a awm.

5. Casting test result neih a ni

(1) Cast test block-a tensile strength test: 485MPa, elongation: 15%, Brinell hardness HB187.

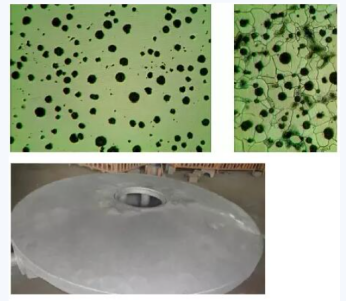

(2) Spheroidization rate chu 95% a ni a, graphite lian zawng chu grade 6 a ni a, pearlite chu 35% a ni. Metallographic structure chu Figure 5-ah hian kan hmu a.

(3) UT leh MT secondary flaw detection-a part pawimawh tak takte recordable defect hmuh tur a awm lo.

(4) A hmel chu a flat a, a hrual bawk (Figure 6 en la), casting defects, sand inclusions, slag inclusions, cold shuts, etc. te a awm lo va, a bang thickness chu a inang tlang a, a dimension te chuan drawing-te mamawh a tlin a ni.

(6) Processing zawhah 20kg/cm2 hydraulic pressure test-ah leakage a awm lo

6. Thutawp

He butterfly valve structural characteristics ang hian a laiah sand core lian tak chu unstable leh awlsam taka deformation leh sand tihfai harsa tak buaina chu process plan design te, sand core siam leh siamthat dan te leh zirconium-based coatings hman te ngaih pawimawh a nih avangin chinfel a ni. Vent holes setting hian casting-a pores awm theihna a veng a ni. Furnace charge control leh runner system atang hian foam ceramic filter screen leh ceramic ingate technology hmangin molten iron thianghlimna a awm thei a ni. Inoculation treatment tam tak hnuah, casting leh chi hrang hrangte metallographic structure The comprehensive performance has reached the standard requirements of customers

AtanginTianjin Tanggu Tui seal valve Co.,ltd. Butterfly valve a ni, gate valve, . Y-strainer hmanga siam a ni, wafer dual plate check valve a nisiam chhuah.

Post hun chhung: Apr-29-2023