Installation dik tak abutterfly valve a nia sealing performance leh service life atan a pawimawh hle. He document hian installation kalphung, ngaihtuah tur pawimawh tak takte chipchiar takin a tarlang a, common type pahnih: wafer-style lehflanged butterfly valve te a awm bawk. Wafer-style valve, stud bolt hmanga pipeline flange pahnih inkara dah te hian dah dan hi a buaithlak zawk hle. Chumi danglamna chu flanged butterfly valve-ah hian integral flanges a awm a, mating pipeline flange-ah direct-in bolt-in a awm a, hei hian a kalphung a ti awlsam hle.

Wafer butterfly valve atana flange bolt te hi a sei deuh hlek a ni. An sei zawng chu hetiang hian chhut a ni: 2x flange thickness + valve thickness + 2x nut thickness. Hei hi wafer butterfly valve ngei pawh hian flanges a neih loh vang a ni. Heng bolt leh nut te hi lakchhuah a nih chuan valve sir lehlamah pipeline te chu a buai ang a, a pangngaiin a thawk thei tawh lo ang.

Flanged valve te hian bolt tawi zawk an hmang a, a sei zawng chu 2x flange thickness + 2x nut thickness tia sawi a ni a, chu chuan valve ngei flange te chu pipeline-a awmte nen direct-in an thlunzawm thei a ni. He design thatna langsar tak chu a sir khat chu a sir lehlamah pipeline hnathawh titawp lovin a inzawm khawm theih a ni.

He thuziak hian wafer butterfly valve byTWS.

Wafer butterfly valve hian design awlsam, compact leh lightweight tak a nei a, a part tlemte chauh a awm. 90° rotation chak takin a thawk a, on/off control awlsam tak a siam thei a, flow regulation tha tak a pe bawk.

I. Install hmaa thupekWafer-Type Butterfly Valve hmanga siam a ni

- Installation tan hmain pipeline-ah hian compressed air hmangin thil dang awm zawng zawng chu tihthianghlim tur a ni a, chumi hnuah tui thianghlim hmanga tihfai tur a ni.

- Valve hman dan chu a performance specification (temperature, pressure) nen a inmil em tih uluk takin enfiah rawh.

- Valve kalna leh sealing surface-ah thil chhe awm leh awm loh enfiah la, paih nghal rawh.

- Unpacking hnuah valve hi dah nghal tur a ni. Valve-a fastening screw emaw nut emaw chu duh duhin thlah suh.

- Wafer type butterfly valve atan chuan butterfly valve flange bik hman a ngai a ni.

- Chumielectric hmanga siam butterfly valve hmanga siam a nipipe-ah eng angle-ah pawh dah theih a ni a, mahse enkawl awlsam zawk nan a sir lam hawia dah loh a tha.

- Butterfly valve flange kan dah dawn hian flange hmai leh sealing rubber te chu a inmil em tih enfiah a pawimawh a, bolt te chu a inang tlang vek tur a ni a, sealing surface pawh a fit kim vek tur a ni. Bolt te chu a ruala tihkhauh loh chuan rubber chu a bulge a, disc chu a jam thei a, disc chu a nawr thei bawk a, chu chuan valve stem-ah leakage a thlen thei bawk.

II.A dahna tur: Wafer Butterfly Valve hmanga siam a ni

Leak-free seal leh butterfly valve him leh rintlak taka hnathawh theih nan a hnuaia installation kalphung hi zawm tur a ni.

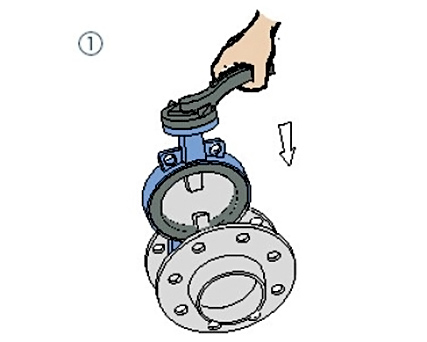

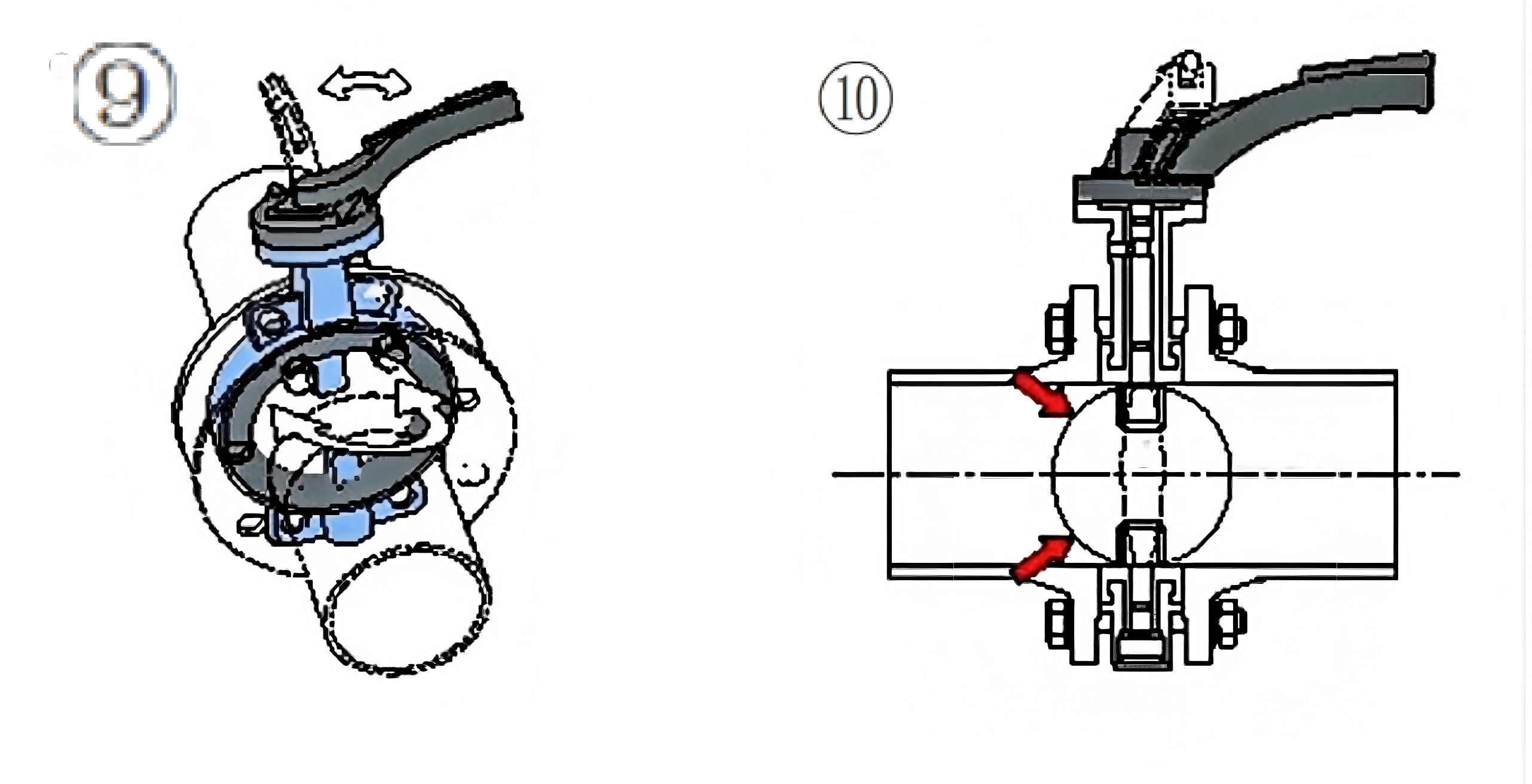

1. A hnuaia kan hmuh ang hian valve chu pre-installed flange pahnih inkarah dah la, bolt holes te chu a inmil tawk em tih enfiah rawh.

2. Bolt leh nut pahnih pali chu flange holes chhungah zawi zawiin dah la, flange chunglam flatness siamthat nan nut te chu tlem tal tikhauh rawh

3. Flange chu pipeline-ah nghet taka nghet turin spot welding hmang ang che.

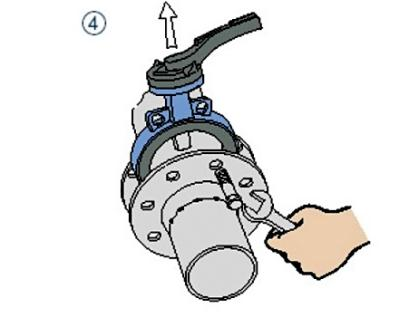

4. Valve chu la chhuak rawh;

5. Flange chu pipeline-ah fully weld rawh.

6. Valve hi welded joint a lum hnuah chauh dah tur a ni. Valve hian flange chhunga kal theihna tur hmun remchang a neih leh nih loh enfiah tur a ni a, valve disc chu degree engemaw chen a inhawng thei tur a ni.

7. Valve awmna tur siamrem la, bolt pahnih pali chu khauh takin khauh rawh (a khauh lutuk loh nan fimkhur rawh).

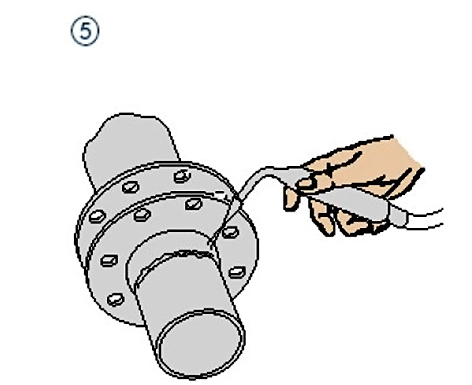

8. Disc chu zalen taka a kal theih nan valve chu hawng la, chutah chuan disc chu tlem han hawng rawh.

9. Cross pattern hmangin nut zawng zawng kha tikhauh rawh.

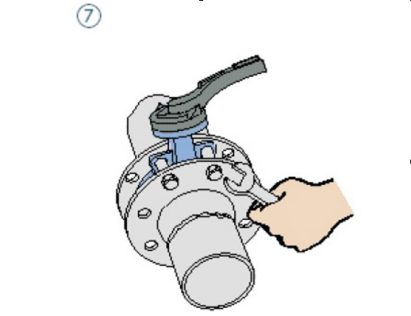

10. Valve chu zalen takin a inhawng thei a, a khar thei tih vawi khat tal nemnghet leh rawh. Note: Valve disc hian pipeline a khawih loh nan enfiah rawh.

Wafer butterfly valve him tak, leak awm lo taka hman theih nan heng thu bulte hi zawm rawh:

- Handle with Care: Valve chu uluk takin dah la, a tlakbuak loh nan.

- Align Precisely: Flange alignment tha tak enfiah la, leak a awm loh nan.

- Tihchhiat loh tur: A dah zawh chuan field chhungah valve chu tihchhiat loh tur a ni.

- Permanent Supports dah: Valve chu a hmuna awm reng tur support hmangin secure rawh.

TWSbutterfly valve quality tha tak tak leh solution kimchang tak a pe agate valve a ni, check valve a ni, lehboruak chhuahna valve te. Valve mamawh zawng zawng tan min rawn biak theih reng e.

Post hun chhung: Nov-08-2025