Lever hman dan Class 150 Pn10 Pn16 Cast Ductile Iron Wafer chi hrang hrang Butterfly Valve Rubber Seat Lined a ni

“Sincerity, Innovation, Rigorousness, and Efficiency” tih hi kan pawlin hun rei tak chhung atan High Quality Class 150 Pn10 Pn16 Ci Di tan thil lei duhtute nen inhmangaih tawnna leh inthlahdahna tur siam dun tura ngaihtuahna nghet tak a ni theiWafer Type Butterfly Valve hmanga siam a niRubber Seat Lined, Khualzin zawng zawngte chu mutual positive aspects bulpui chungchangah company inzawmna min ruahmansak turin thinlung takin kan lo lawm a che. Tunah hian min rawn biak theih reng e. Darkar 8 chhungin kan skilled reply hi i hmu thei ang.

“Sincerity, Innovation, Rigorousness, and Efficiency” tih hi kan pawlin hun rei tak chhunga thil lei duhtute nena inpawh tawnna leh inhmang tawnna atana insiamrem tura kan ngaihdan nghet tak a ni theibutterfly valve;wafer chi hrang hrang butterfly valve, “Zero defect” tih tumna nen. Environment enkawl tur, leh social returns, care employee social responsibility chu mahni tih tur angin enkawl tur a ni. Khawvel hmun hrang hrang atanga ṭhiante rawn tlawh leh min kaihruai turin kan lo lawm a, chutiang chuan hnehna chang tura kan tum chu kan hlen chhuak thei ang.

Hrilhfiahna:

YD Series Wafer butterfly valve 's flange connection hi universal standard a ni a,a handle material chu aluminium a ni;Medium pipe hrang hranga flow cut-off emaw regulate emaw atana hmanraw atan hman theih a ni. Disc leh seal seat-a thil chi hrang hrang thlan hmangin, chubakah disc leh stem inkara pinless connection hmangin,valve hi dinhmun chhe zawkah hman theih a ni a, chu chu desulphurization vacuum, tuifinriat tui desalinization te hi a ni.

Valve hi design compact leh lightweight tak a ni a, install leh hman a awlsam hle. A wafer-style configuration hian flanges inkarah rang leh awlsam taka dah theihna a siam a, tight space leh weight-conscious application atan a tha hle. Torque mamawh tlem avangin hmanrua te chu stress ngai lovin flow dik taka control turin valve awmna chu awlsam takin an siamrem thei a ni.

Kan wafer butterfly valve-te thil langsar ber chu an flow control theihna tha tak hi a ni. A disc design danglam tak hian laminar flow a siam a, pressure drop a ti tlem a, performance efficiency a ti sang bawk. Hei hian i system performance a ti tha mai bakah energy consumption a tihtlem bakah i operation atan sum senso nasa tak a humhim thei a ni.

Industrial environment eng pawhah hian himna hi a pawimawh ber a, kan wafer butterfly valve te hian i mamawh a phuhruk thei a ni. Safety locking mechanism hmanga thuam a ni a, hei hian accident emaw phalna nei lo emaw valve hnathawh a veng thei a, i process chu engmah tihbuai lohvin a kal tluang thei a ni. Tin, a tight sealing property hian leakage a ti tlem a, overall system rintlakna a tipung a, downtime emaw product contamination hlauhawmna a ti tlem bawk.

Kan wafer butterfly valve-a thil langsar dang pakhat chu versatility a ni. Tui tihthianghlim, HVAC system, chemical processing, oil leh gas, leh a dangte pawh huamin hmanraw hrang hrang atan a tha a, valve te hian industry hrang hrang tan control solution rintlak, tha tak a pe a ni.

A tawi zawngin, kanrubber thut wafer butterfly valve a nis chuan hmanraw hrang hrang atan flow control solution rintlak, performance sang leh man tlawm zawk a pe a ni. A sakna nghet tak, a dah awlsamna, flow control theihna sang zawk leh himna tha tak tak a neih avangin he valve hian rinhlelh rual lohvin i beisei aia nasain a thawk ang a, i hnathawhna kawngah pawh a pawimawh hle ang. Kan wafer butterfly valve-te hnathawh dan danglam bik chu tawng la, i industrial process-te chu sang zawkah hruai rawh.

A mizia: 1.1.

1. A size a te&light in leh maintenance awlsam tak a ni. A tulna hmun apiangah mount theih a ni.

2. A structure awlsam, compact tak, 90 degree on-off operation rang tak a ni

3. Disc hian two-way bearing a nei a, seal tha tak a nei a, pressure test hnuaiah leakage a nei lo.

4. Flow curve chu straight-line lam hawia kal. Regulation performance tha tak a nei.

5. Thil chi hrang hrang, media hrang hranga hman theih.

6. Wash leh brush resistance chak tak, leh hnathawhna hmun chhe takah pawh a fit thei.

7. Center plate structure, torque te tak te in hawn leh khar.

8. Rawngbawlna hun rei tak. Opening leh closing operation sang sawm tam tak test-naah ding chhuak.

9. Media cut off leh regulate-naah hman theih a ni.

A hman dan tlangpui:

1. Tui hnathawh leh tui lakna project

2. Environment humhalh

3. Mipui hmanraw hman tur

4. Power leh Public Utilities te

5. In sakna industry

6. Petroleum/ Chemical lam thil a ni

7. Thir hmanga siam. Metallurgy lam thil a ni

8. Paper siamna industry

9. Chaw/In tur etc

A zau zawng: 1.1.

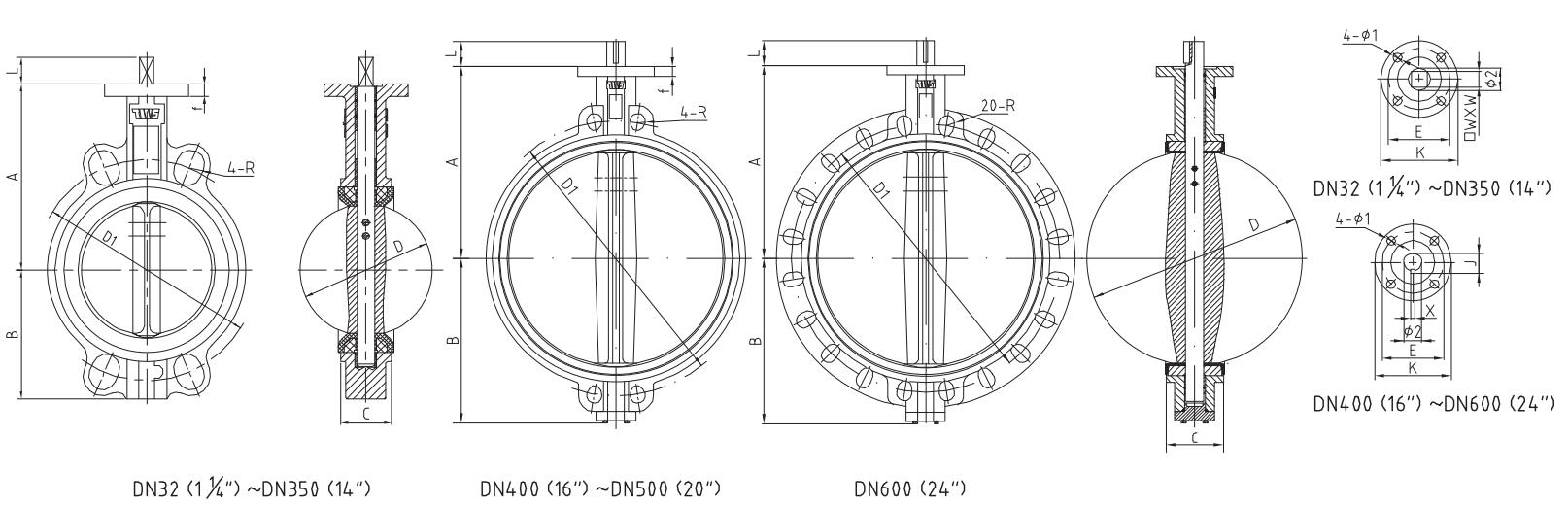

| Lenzawng tehna | A | B | C | D | L | D1 | D2 | Φ1 a ni | ΦK tih a ni | E | R1 (PN10) a ni. | R2 (PN16) a ni. | Φ2 a ni | f | j | x | □w*w tih a ni | A rih zawng (kg) . | |

| mm | inch a ni | ||||||||||||||||||

| 32 | 11/4 a ni | 125 a ni | 73 | 33 | 36 | 28 | 100 a ni | 100 a ni | 7 | 65 | 50 | R9.5 a ni | R9.5 a ni | 12.6 | 12 | – | – | 9*9 a ni | 1.6 |

| 40 | 1.5 | 125 a ni | 73 | 33 | 43 | 28 | 110 a ni | 110 a ni | 7 | 65 | 50 | R9.5 a ni | R9.5 a ni | 12.6 | 12 | – | – | 9*9 a ni | 1.8 |

| 50 | 2 | 125 a ni | 73 | 43 | 53 | 28 | 125 a ni | 125 a ni | 7 | 65 | 50 | R9.5 a ni | R9.5 a ni | 12.6 | 12 | – | – | 9*9 a ni | 2.3 |

| 65 | 2.5 | 136 a ni | 82 | 46 | 64 | 28 | 145 a ni | 145 a ni | 7 | 65 | 50 | R9.5 a ni | R9.5 a ni | 12.6 | 12 | – | – | 9*9 a ni | 3 |

| 80 | 3 | 142 a ni | 91 | 46 | 79 | 28 | 160 a ni | 160 a ni | 7 | 65 | 50 | R9.5 a ni | R9.5 a ni | 12.6 | 12 | – | – | 9*9 a ni | 3.7 |

| 100 a ni | 4 | 163 a ni | 107 a ni | 52 | 104 a ni | 28 | 180 a ni | 180 a ni | 10 | 90 | 70 | R9.5 a ni | R9.5 a ni | 15.8 a ni | 12 | – | – | 11*11 a ni | 5.2 |

| 125 a ni | 5 | 176 a ni | 127-ah a awm | 56 | 123 a ni | 28 | 210 a ni | 210 a ni | 10 | 90 | 70 | R9.5 a ni | R9.5 a ni | 18.9 a ni | 12 | – | – | 14*14 a ni | 6.8 |

| 150 a ni | 6 | 197-ah a awm | 143-ah a awm | 56 | 155-ah a awm | 28 | 240 a ni | 240 a ni | 10 | 90 | 70 | R11.5 a ni | R11.5 a ni | 18.9 a ni | 12 | – | – | 14*14 a ni | 8.2 |

| 200 a ni | 8 | 230 a ni | 170 a ni | 60 | 202 a ni | 38 | 295 a ni | 295 a ni | 12 | 125 a ni | 102 a ni | R11.5 a ni | R11.5 a ni | 22.1 | 15 | – | – | 17*17 a ni | 14 |

| 250 a ni | 10 | 260 a ni | 204 a ni | 68 | 250 a ni | 38 | 350 a ni | 355 a ni | 12 | 125 a ni | 102 a ni | R11.5 a ni | R14 a ni | 28.5 a ni | 15 | – | – | 22*22 a ni | 23 |

| 300 a ni | 12 | 292 a ni | 240 a ni | 78 | 302 a ni | 38 | 400 a ni | 410 a ni | 12 | 125 a ni | 102 a ni | R11.5 a ni | R14 a ni | 31.6 | 20 | – | – | 22*22 a ni | 32 |

| 350 a ni | 14 | 336 a ni | 267 a ni | 78 | 333 a ni | 45 | 460 a ni | 470 a ni | 14 | 150 a ni | 125 a ni | R11.5 a ni | R14 a ni | 31.6 | 20 | 34.6 | 8 | – | 43 |

| 400 a ni | 16 | 368 a ni | 325 a ni | 102 a ni | 390 a ni | 51/60 a ni | 515 a ni | 525 a ni | 18 | 175 a ni | 140 a ni | R14 a ni | R15.5 a ni | 33.2 | 22 | 36.2 | 10 | – | 57 |

| 450 a ni | 18 | 400 a ni | 356 a ni | 114 a ni | 441 a ni | 51/60 a ni | 565 a ni | 585 a ni | 18 | 175 a ni | 140 a ni | R14 a ni | R14 a ni | 38 | 22 | 41 | 10 | – | 78 |

| 500 a ni | 20 | 438 a ni | 395 a ni | 127-ah a awm | 492 a ni | 57/75 a ni | 620 a ni | 650 a ni | 18 | 175 a ni | 140 a ni | R14 a ni | R14 a ni | 41.1 a ni | 22 | 44.1 a ni | 10 | – | 105 a ni |

| 600 a ni | 24 | 562 a ni | 475 a ni | 154 a ni | 593 a ni | 70/75 a ni | 725 a ni | 770 a ni | 22 | 210 a ni | 165 a ni | R15.5 a ni | R15.5 a ni | 50.6 a ni | 22 | 54.6 a ni | 16 | – | 192-ah a awm |

“Sincerity, Innovation, Rigorousness, and Efficiency” tih hi kan pawlin hun rei tak chhunga a ngaihdan nghet tak chu a ni thei a, shoppers te nen mutual reciprocity leh mutual advantage atan High Quality Class 150 Pn10 Pn16 Ci Di Wafer Type Butterfly Rubber Seat Lined Valve atan kan din dun theih nan, We sincerely welcome all guests to arrange company relationships with us about the basis of mutual positive aspect hrang hrang a awm bawk. Tunah hian min rawn biak theih reng e. Darkar 8 chhungin kan skilled reply hi i hmu thei ang.

Wafer Type Quality tha tak a niButterfly Valve a ni, “Zero defect” tih tumna nen. Environment enkawl tur, leh social returns, care employee social responsibility chu mahni tih tur angin enkawl tur a ni. Khawvel hmun hrang hrang atanga ṭhiante rawn tlawh leh min kaihruai turin kan lo lawm a, chutiang chuan hnehna chang tura kan tum chu kan hlen chhuak thei ang.